- Specialist in Large Volume Orders

- 25 Years of Manufacturing Experience

- UK-Based Factory with 7 Acre Site

- In-House Technical Design Team

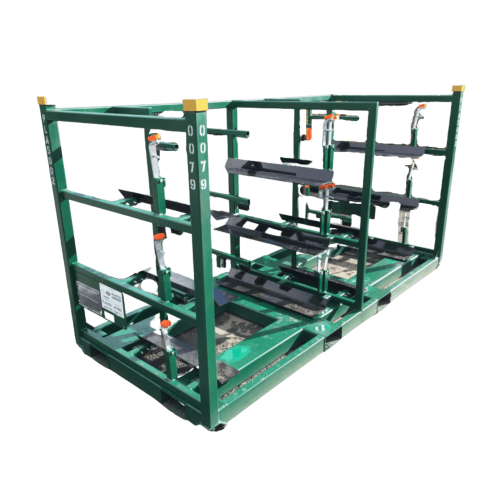

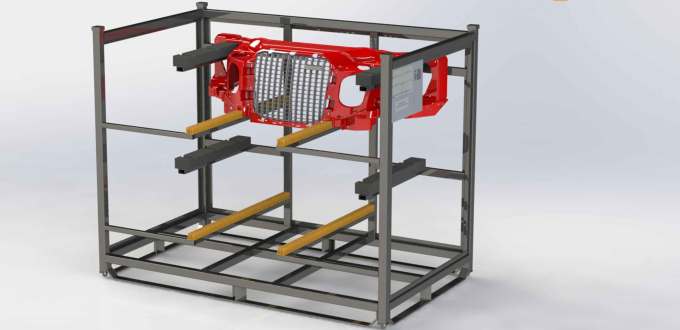

JS Burgess is one of the largest UK based manufacturers of stillages and has extensive experience in the design, manufacture and supply of Automotive Stillages to Tier Suppliers or direct to Automotive Companies as part of line side equipment.

Specialising in large production runs and complex projects, we have designed and manufactured many different types of automotive stillages and deploy a number of standard and innovative dunnage systems to ensure safe transportation of components and to minimise defects.

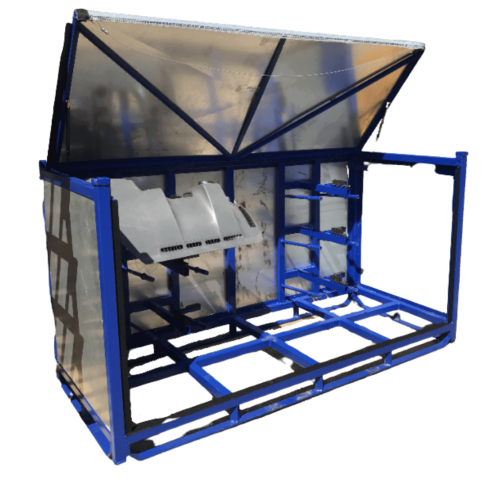

Our in-house Design team and Engineers also ensure our Automotive Stillages are finished to a high standard taking into account the safety of the operatives, speed of operation, weatherproofing and also transport efficiency.

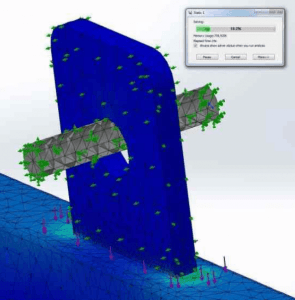

We design bespoke products from CAD using STEP or your chosen interchange format and we go to great lengths to maximise “pack factor” and minimise sources of potential defects. We also are able to reproduce a stillage from a sample or drawing and our expertise in manufacture allows us to provide competitive and reliable services.

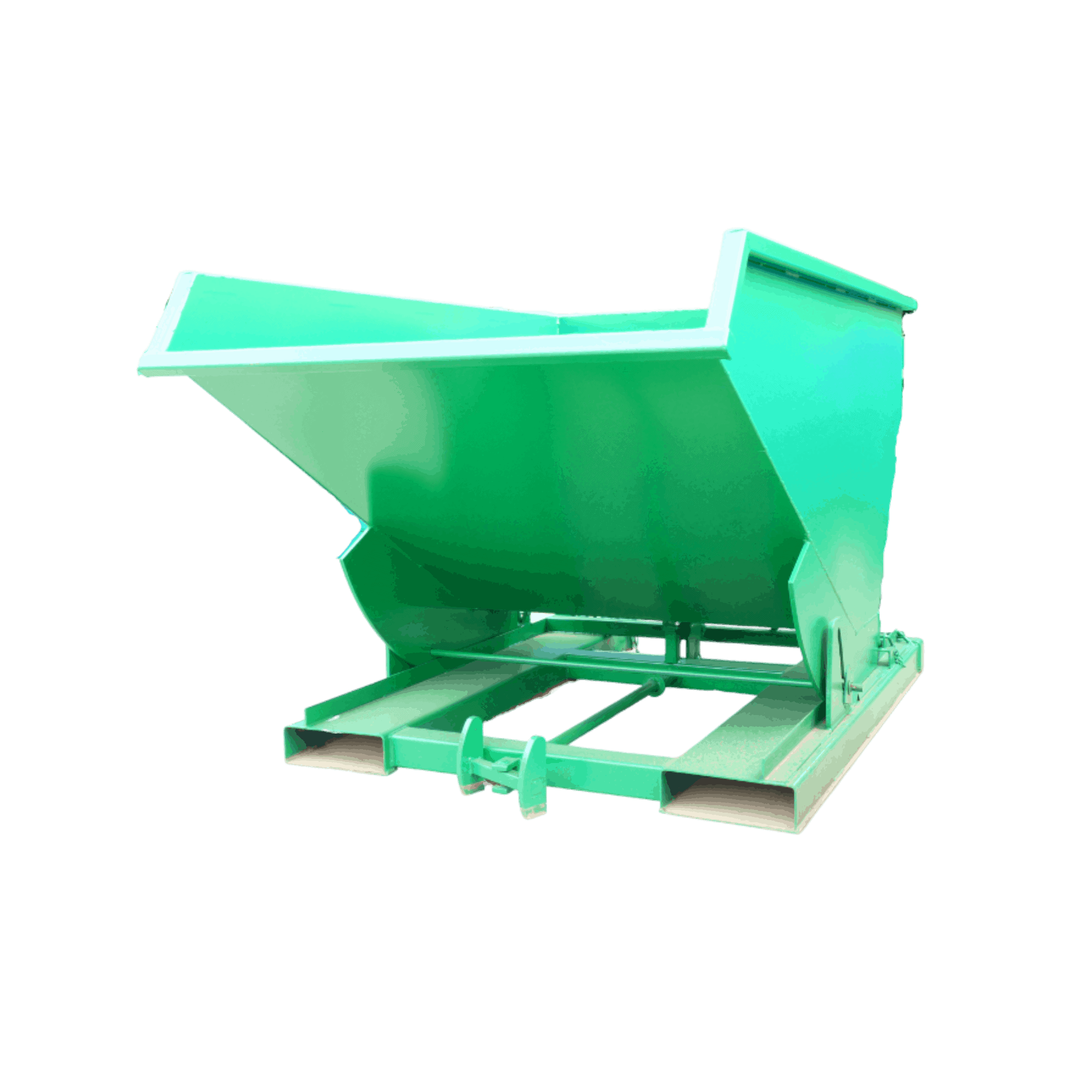

Automotive Stillages are metal framed packaging solutions which are often used ‘line-side’ in car factories and by tiered suppliers as part of their supply chain.

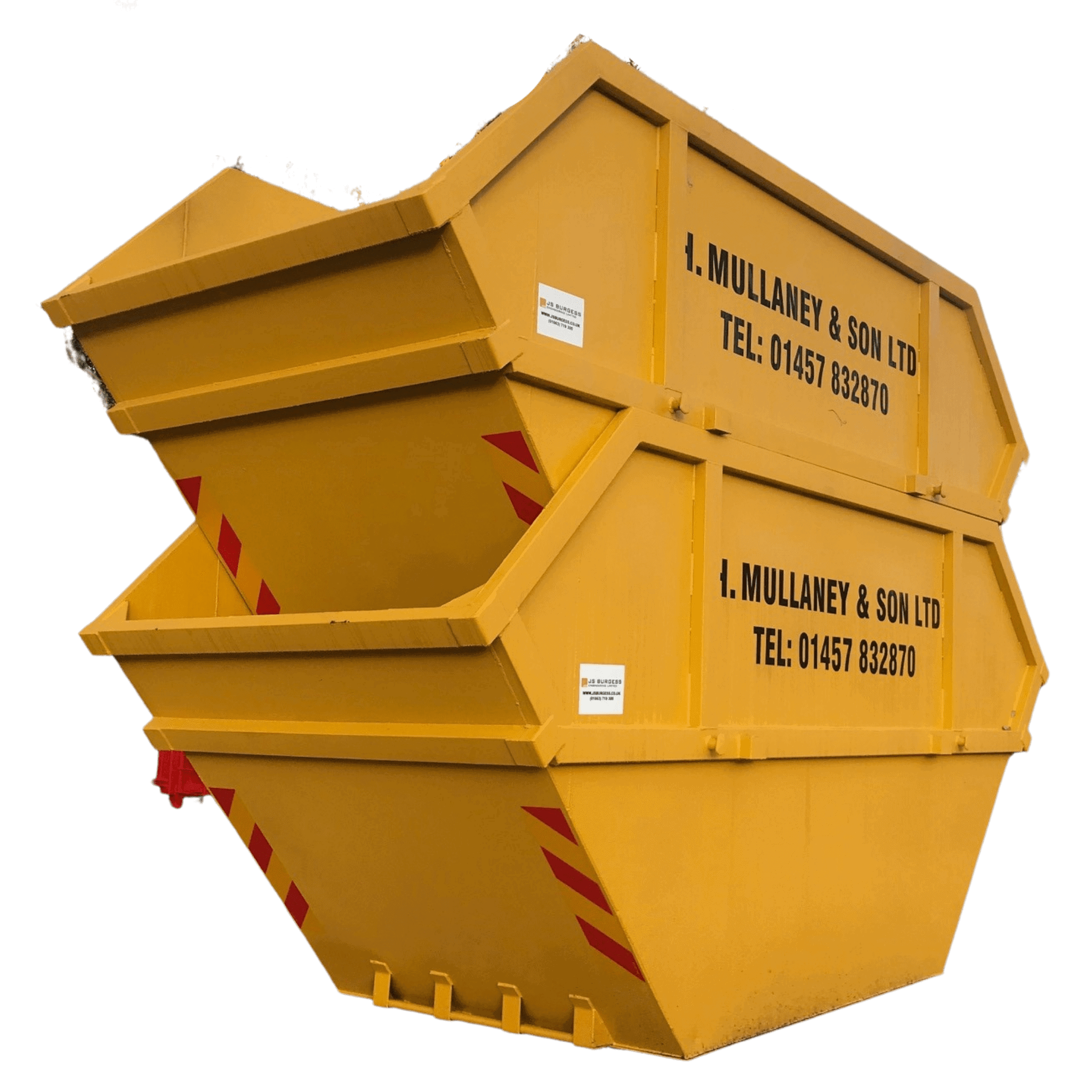

JS Burgess Engineering has extensive experience producing Automotive Stillages which have been used for a range of components for customers such as JLR (Jaguar Land Rover), Nissan and Infiniti and blue-chip 3PL companies.

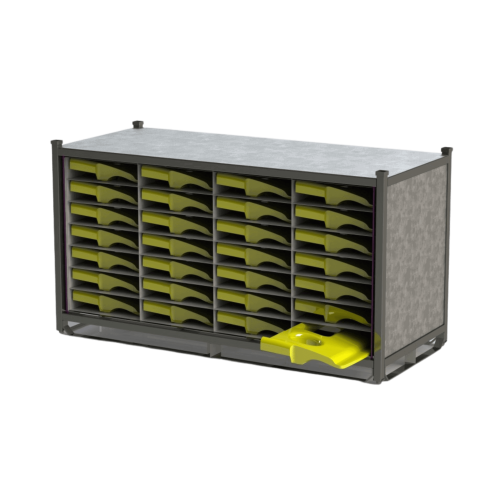

Custom Made Dunnage

One of the most complex parts of Automotive Stillages is the “dunnage”’; these are soft components that are applied onto the Stillage and support and protect the parts from the first tier suppliers to their point of use on the assembly line.

There are innumerable different types of dunnage systems such as textiles, bag systems, euroboxes and custom PU dunnage. JS Burgess’s technical teams work directly with our customers to find the most effective and cost efficient solution and we have in-house designers experienced in automotive packaging solutions and Solidworks Computer Aided Design software for bespoke solutions.

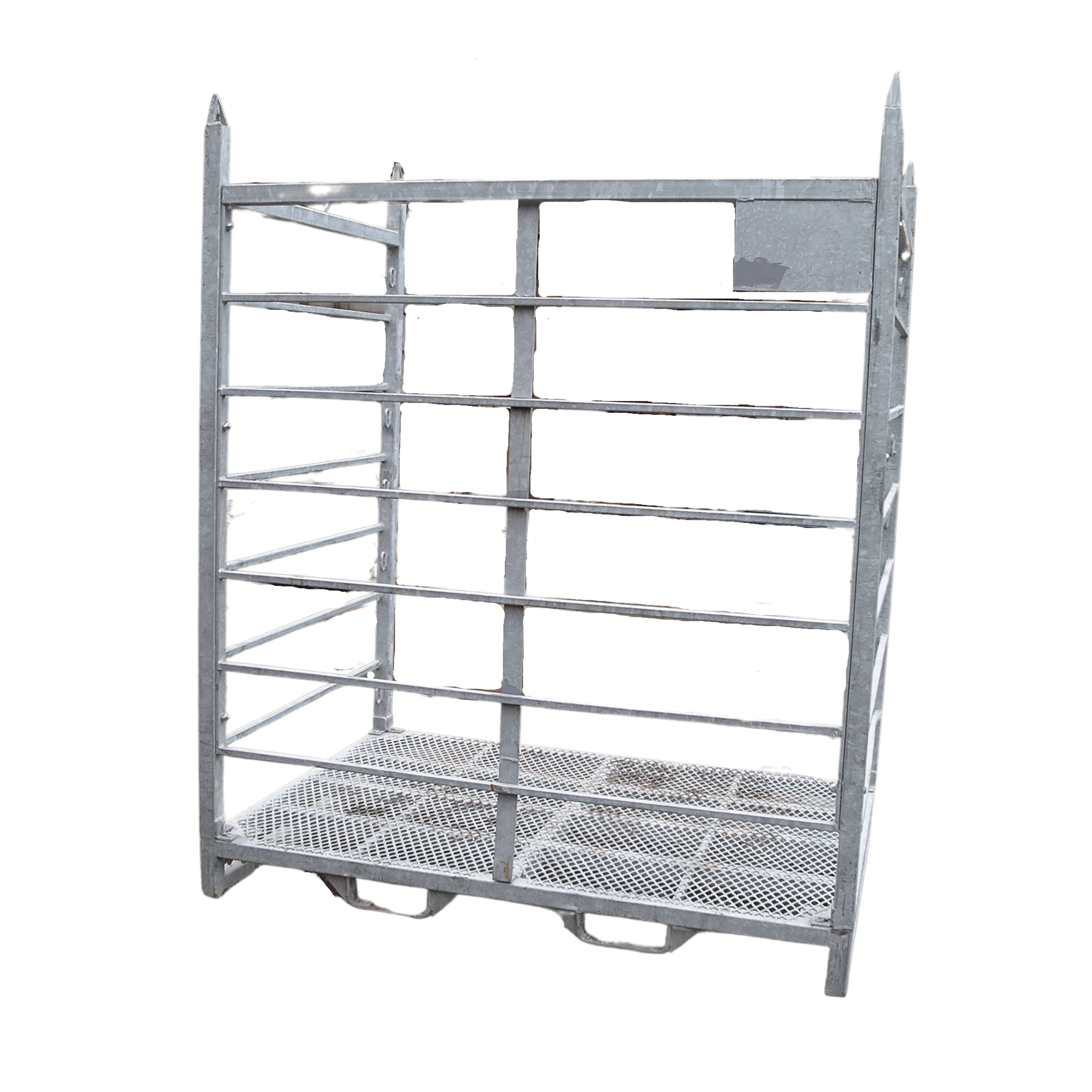

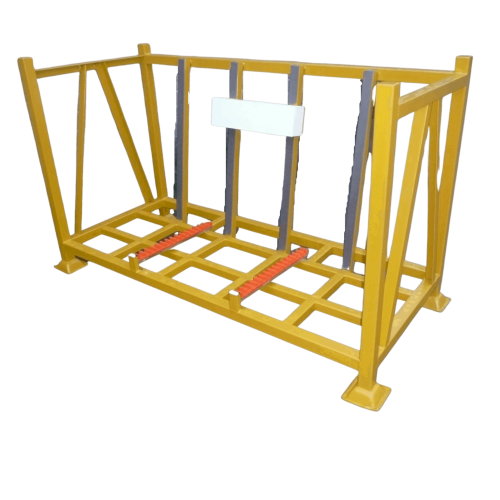

The images below show custom foam and rubber brushes which secure automotive parts in place on the Stillage and ensure that no damage occurs on the delicate ‘A-side’ of the part.

Tried and Tested Stillages for Exacting Demands

Due to the nature of the automotive industry, line-side packaging and Stillages need to work first time, every time and protect the high surface finishes that the buyers of new vehicles expect.

JS Burgess employs full time fabricators and sample hands for the production of prototypes and approval first offs and make effective use of tube laser components for accuracy and the elimination of sharp edges.

Why choose JS Burgess for your Automotive Stillages?

Here at JS Burgess, we have been manufacturing Stillages for many years. We have extensive experience in designing, manufacturing and supplying Automotive Stillages to Tier Suppliers and direct to Automotive Companies as part of line-side equipment.

If you’re looking for an Automotive Stillage for your business, we can help. For help and enquiries please call us on +44 1663 719 300 or email us at enquiries@jsburgess.co.uk and a member of our specialist team will be in touch.

The information on this website is not exhaustive so please don’t hesitate to call us on 01663 719 300 should you have any questions, require a quotation or wish to discuss a specific project with us. We’d be delighted to help. Or alternatively please fill out the form below and we will respond to you shortly.